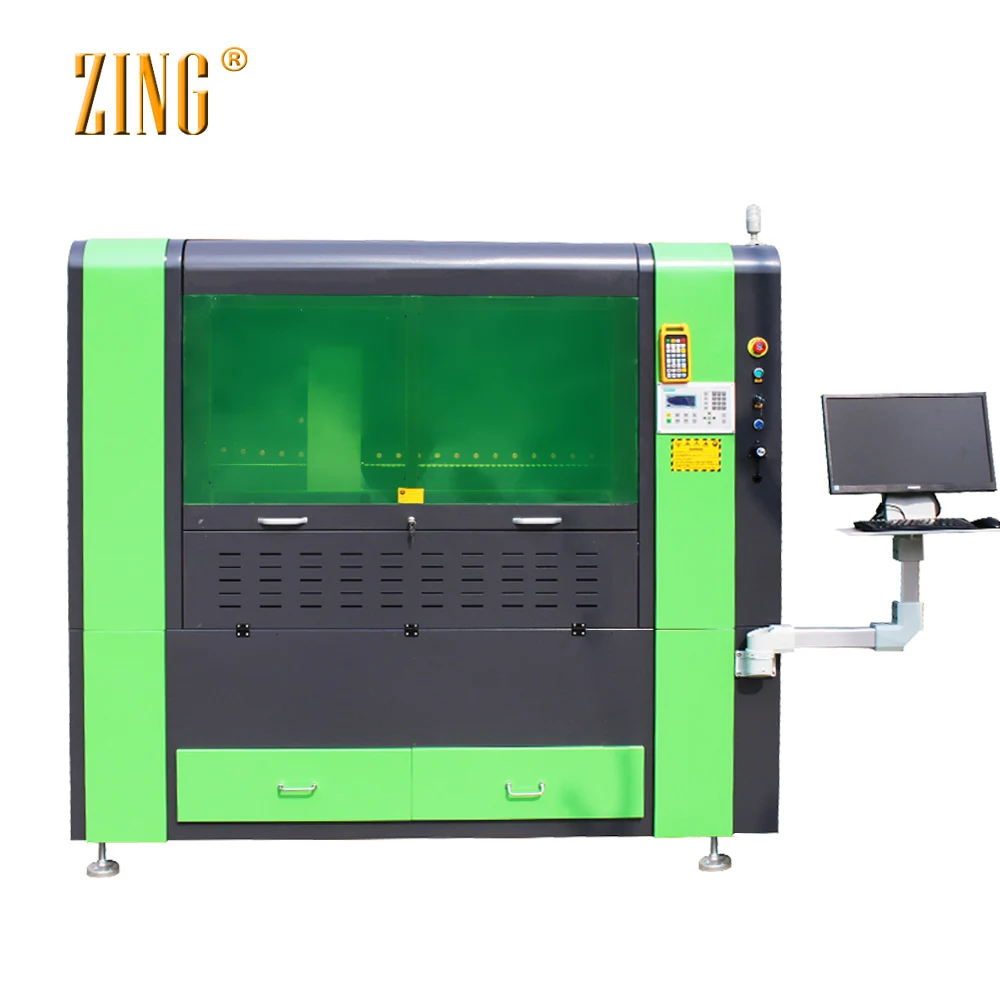

Product features:

1.Whole Machine welded bed structure,Stable performance,could ensure the stable operation of equipment

2.After 650℃ high temperature heat treatment Machine bed, adopt large Gantry milling accuracy process, ensure machine bed stability and smoothness.

3.Operating system, man-machine interface, easy to operate

4.High quality, high efficiency fiber laser producer. low processing cost and energy conservation and environment protection

5.Servo drive,The structure of the machine tool adopts rack and pinion drive,Ensure equipment high speed , high accuracy, and high reliability

6.Fast delivery1kw high power CNC metal sheet pipe fiber laser cutting machine , 300W, 500W, 750W, 1000W, 1500W, 2000W, 3000W, 6000W, 8000W fiber laser power available

7. laser cutting machine adopts IPG, N-light, RAYCUS fiber laser source brand available

8. High speed, high accuracy, stable performance, best quality

9. Support Factory Inspection

The Segmented Rectangular Tube Welded Bed

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, it also increases the resistance and stability of the guide rail so as to effectively avoid the deformation of the bed.

*High strength, stability, tensile strength, ensuring 20 years of use without distortion;

*Thickness of rectangular pipe wall is 10mm,and weights 4500 kg.

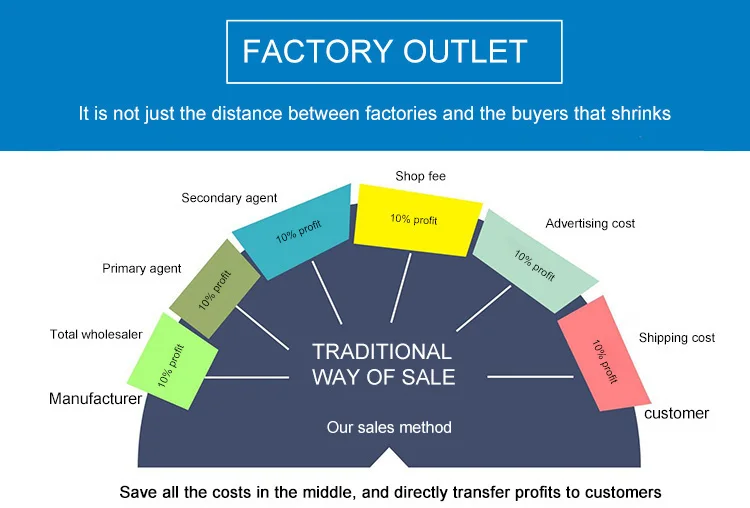

Low Cost:

(1) High photo-voltaic conversion rate (above 30%), which helps to save electricity and costs greatly to guarantee the highest production efficiency.

(2) When processing, the laser only consumes electricity and doesn’t need extra gas, bringing the minimum operation and maintenance costs.

(3) Adopting semiconductor modular and redundancy design, without any optical glass in resonant cavity and without start time, so it is in high stability and doesn’t need adjusting and maintaining, which saves the costs and time. In this point, the traditional laser is not comparable.

(4) The output wavelength of fiber laser is 1.06μm, which is a tenth of CO2wavelength. The output beam is in high quality and power density, so it is easy to be absorbed by metal materials and therefore has great power to cut and weld to make the lowest processing costs.

Advantages:

1. Moving crossbeam, imported high precision racks and linear guide rail, stable transmission, high precision.

2. Machine frame, crossbeam and worktable adopt integral welding structure.

3. X, Y and Z axes use imported Japan servo motor with high precision and speed.

4. Using professional and powerful Shanghai Cypcut fiber cutting controlling system that based on Windows operating system, with good Human Machine Interaction and easy operation.

5.Laser is produced without gas and it could use air to cut sheet metal.

fiber machineprice is decreasing from last several years, and makes its price is acceptable for most factories and customers. Some years before,fiber laser cutting machineprice is very high, so many factories choose 2kw to 5kw co2 laser cutting machine for their metal sheet cutting, but its maintanance cost for co2 laser is very high. At present, many factories are considering to change their co2 laser cutting machine tofiber laser cutting machinebecause of its easy operating and low cost for maintanance. At the same time,fiber laser cutting machineown much longer lifetime than co2laser cutter.For example, lifetime for fiber laser source is 50,000 to 100,000 hours, that means it can work more than 10 years at least if the machine works 12 hours each day. However, lifetime for co2 laser tube is only 10,000 to 20,000 hours, that's why the demond and market forfiber laser cutting machineis increacing much recently.

Cutting scope |

1300x900mm |

Cutting Speed(max) |

15m/Min |

Cooling model |

Water cooling with high precision constant temperature water chiller |

Laser power |

500W |

Fiber laser generator |

Chinese Raycus |

Laser head |

BT240S |

Control system |

FS full-closed loop servo control |

Machine dimension |

2200mm*5200mm*1900mm |

Continuous Operating Hours |

24h |

Industry Applications:

Used for cutting a variety of metal plates, mainly used in stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass, aluminum, various alloy plate, rare metal and other metal materials.

Z1530Ffiber laser cutting machine can carry up to 8000W laser power, so cutting some thick plate, it is a very good choice. For example, agricultural machinery, textile machinery, food machinery and construction machinery and other large machinery and equipment manufacturing, usually use high power fiber laser cutting machine for processing.

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, aluminum-plating, zinc plate, copper and other metals.

In addition, it possesses high brightness levels and lower reflectivity as well as solid glass panel sturdiness and durability.

Our wooden case is after fumigation treatment.Needn’t timber inspection,saving shipping time.

Model |

Machine size(L*W*H) |

Packing size(L*W*H) |

Z6040 |

1460*810*900mm |

1600*950*1100 |

Z9060 |

1710*1010*900mm |

1800*1160*1100 |

Z1390 |

1760*1310*900mm |

1850*1460*1100 |

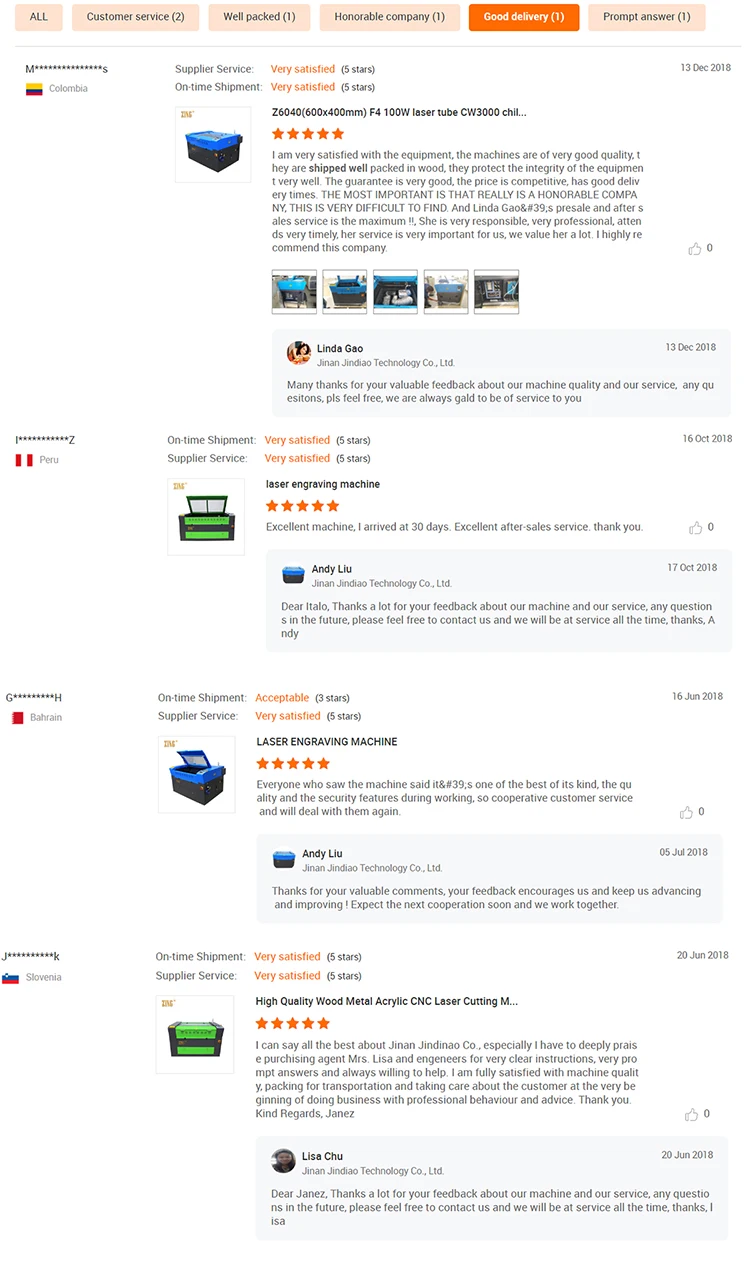

5 STAR HIGH PRAISE

Lisa will be at service all the time, ConTACT US NOW