3mm basswood plywood 3d puzzle by laser cutting machine

1. Fast speed than handle making

2.Cutting quality good together with high accuracy. Computer control easy for complex design.

3. Self-design keeps same space from up to down as well as straight with surface. Small laser dot keeps thinner cutting lines.

4. Adjustable for working speed and laser power, change setting up easily.

Products model |

Z6040 |

Z9060 |

Z1390 |

Working area |

600x400mm |

900x600mm |

1300x900mm |

Laser Types |

Hermetic And Detached CO2 Laser Tube |

||

Engraving speed |

0-75,000mm/min |

||

Cutting speed |

0-40,000mm/min |

||

Location precision |

≤0.01mm |

||

Resetting positioning accuracy |

≤0.01mm |

||

Power supply |

AC 220V/50~60Hz (110V is optional) |

||

Gross power |

<1,000W |

||

Operating temperature |

0 - 45° |

||

Operating humidity |

5 - 95% |

||

Minimum shaping character |

English 1×1mm |

||

360°slope engrave |

YES |

||

Motors driving system |

Stepper (servo is optional) |

||

Cooling mode |

Water-cooling and protection system |

||

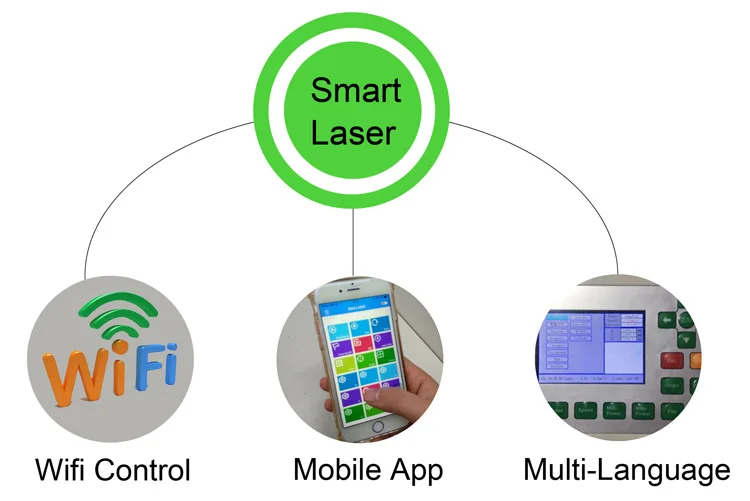

Operating system |

Windows XP, VISTA, Windows7, Windows8 |

||

Software |

RDWorksV8(compatible with CorelDraw, AutoCad, Illustrator, PS) |

||

Graphic format supported |

DXF,AI,PLT,DST,DSB,CDR,BMP,JPG,GIF,PNG,MNG etc |

||

Standard accessories |

Water pump, air pump, exhaust fan, water pump |

||

Optional parts |

Electrical up/down table, rotary clamp, red light pointer, water chiller |

||

Special Features:

Taiwan square rail, square tube framework machine body, new high efficiency laser tube, red light positioning, advanced DSP control system, ensure high speed, high precision operation, and high work efficiency!

1. X&Y axis with HIWIN high accuracy square rail, perfect performance.

2.only manufacturer adopts square tube framework machine body 40% higher than simple iron sheet structure, never distortion. Prevents machine from quivering and resonance during long time work.

3. High efficiency tube with stable laser path, life time reaches to 10000 hours.

4. Red cross point offers highest accuracy position.

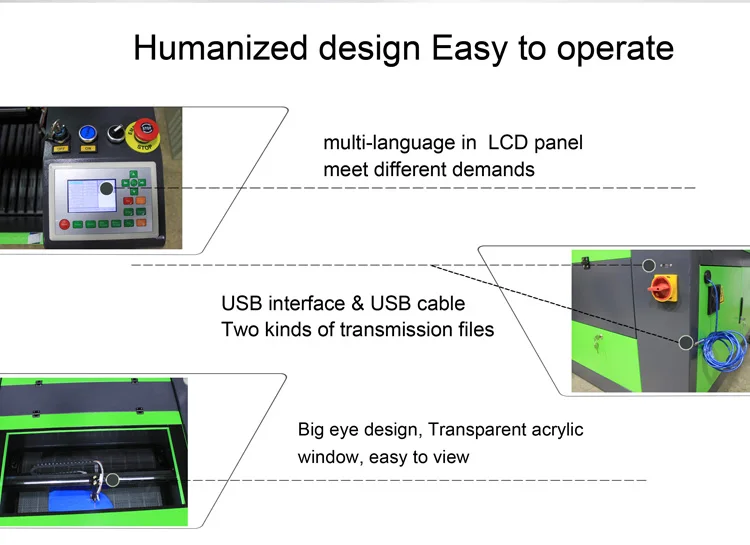

5. Humanized and modern design makes work happy, safe and easy.

6. Transparent acrylic watching door, easy checking work process.

7. Professional motion control card offers continue fast curve cutting together with shortest path selection. Shorten work time.

Our wooden case is after fumigation treatment.Needn’t timber inspection,saving shipping time.

Model |

Machine size(L*W*H) |

Packing size(L*W*H) |

Z6040 |

1460*810*900mm |

1600*950*1100 |

Z9060 |

1710*1010*900mm |

1800*1160*1100 |

Z1390 |

1760*1310*900mm |

1850*1460*1100 |

Our Service:

| 1. Guarantee for 2 years. |

| 2.Maintenance free of charge for 2 years . |

| 3. We will provide the consumable parts at an agency price. |

| 4. 24 hours online service, free technical support. |

| 5. Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me. |

| 6. We have manual instruction and CD (Guiding Videos) for software Installation, operation and machine's using and maintenance. |

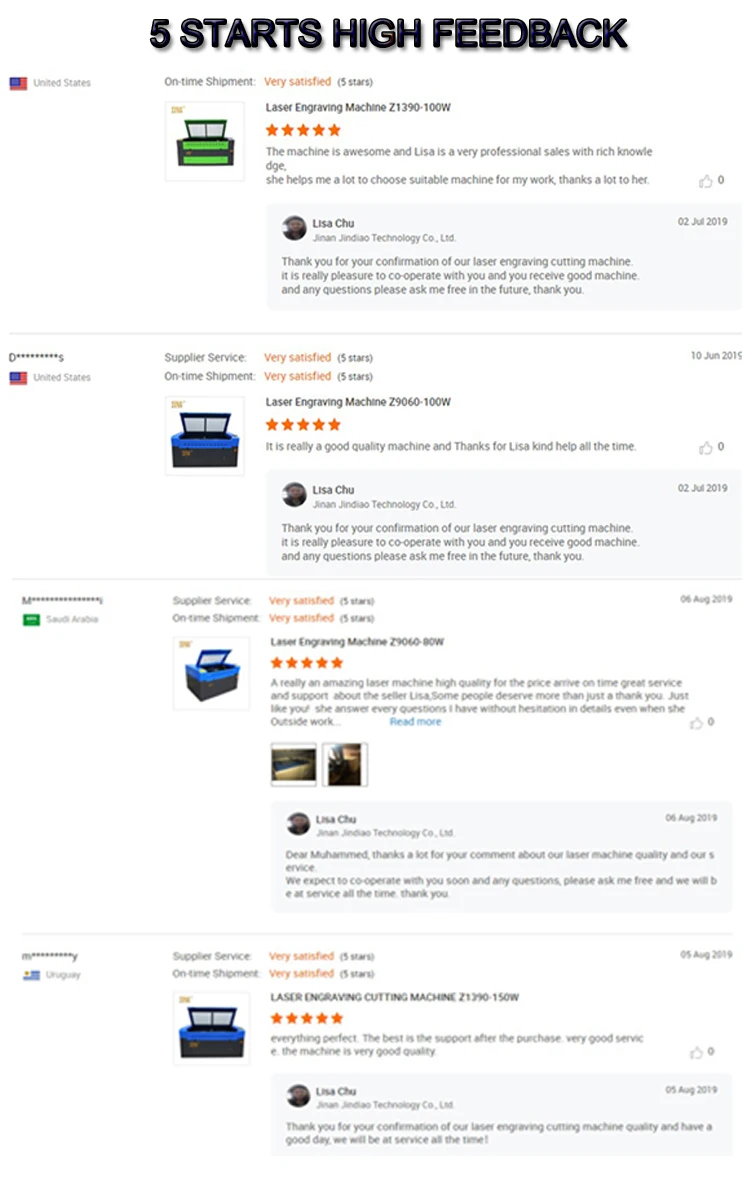

Q1: I knew nothing about this machine, what kind of machine i should choose?

Very easy to choose. Just tell us what you want to do by using CNC laser machine, then let us give you perfect solutions and suggestions.

Q2: When I got this machine, but I don’t know how to use it. What should I do?

We will send video and English manual with the machine. If you still have some doubts, we can talk by telephone or skype and e-mail.

Q3: If some problems happen to this machine during warranty period, what should I do?

We will supply free parts during machine warranty period if machine have some problems. While we also supply free life long after-sales service. So any doubts, just let us know, we will give you solutions.

Q4: Before sending me an inquiry on our cnc laser, it is better for you to provide me the following information

1)Your metal or non-metal material size. Because in our factory, we have different models according to working area.

2)Your materials.

我tal/Acrylic/plywood/MDF?

3)你想engrave or cut?

If cut, could you tell me your cutting thickness? Because different cutting thickness need different laser tube power and laser power supplier.