The single head stone engraving machine uses Taiwan linear navigation, linear rail bearing surface contact, long-term use of high precision.

Single head stone carving machine adopts German double nut automatic clearance ball screw. High speed driver, fast speed, powerful.

The dust-proof and oil injection structure of this machine effectively ensures the long-term operation of machinery. This machine has the function of breaking point, cutting tool and carving continually. It can carve freely at any position.

The machine adopts high-power frequency conversion water-cooled spindle, which can effectively process hard materials.

2. Product Parameter(Specification) of the Single Head Stone Engraving Machine

Rated input power |

6000 |

No-load speed: |

24000 |

Plunger travel length |

1300 * 2500 |

Diameter of base plate |

standard |

Rated voltage |

380 |

Turnover number |

0-24000 |

Power supply type |

The ac power |

Milling cutter diameter |

3.175 to 12.7 |

Collet chuck |

The knife clip |

Height |

300 |

Scope of application |

Natural marble, wood, density board, granite |

Processing and customization |

yes |

Spindle speed |

6000-6000 |

Net weight |

1800 |

Type |

Engraving machine |

Work form |

Fully automatic |

Product type |

new |

Rated power |

6000 kw |

Dimensions |

1300 * 2500 * 150 mm |

Maximum machining length |

Maximum machining length |

Maximum machining thicknes |

150 mm |

Maximum machining widt |

1300 mm |

Machine weight |

1200 kg |

Feeding speed |

15000 |

3. Product Feature And Application of the Single Head Stone Engraving Machine

1 . imported Taiwan straight-line square guide rail, double row four-row slider, bearing large gravity, stable operation, high accuracy, long life, accurate cutting.

2 . The three-dimensional rotating shaft adopts a new installation structure, which can be pushed and pulled by fixing on the table surface and is easy to use. Double screw rod and double guide rail are used to reinforce the two sides, which greatly increases the bearing capacity of the rotating shaft.

3 . High power spindle, constant power, low noise, greatly improve work efficiency

4 . CNC digital control, with break point memory function, to ensure that the accident (knife break) or the next day to continue to work.

5 . Stone engraving machine with automatic oil injection, limit,Protect slider with dust-proof function.

6 . The utility model has the advantages of low cost, powerful function and wide application.

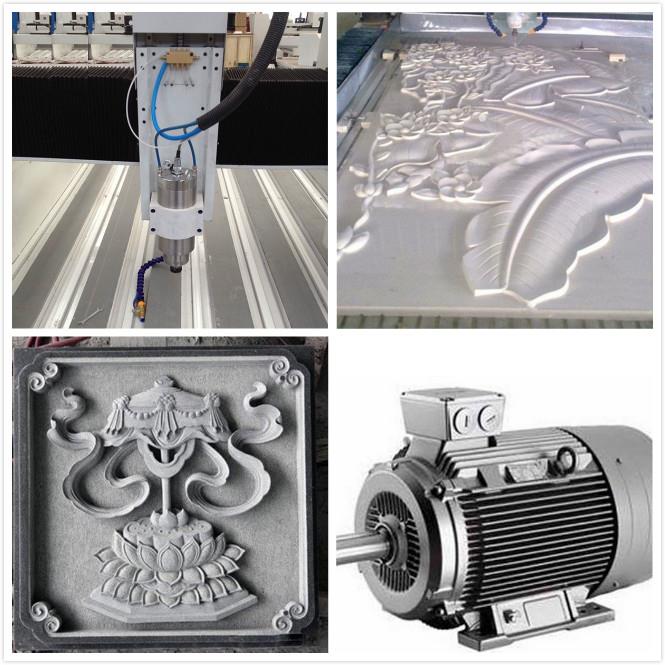

4 . Production Details of the Single Head Stone Engraving Machine

The single head stone engraving machine is applicable to stone industry, stone tablet processing industry, art relief, advertising industry, decoration and decoration industry, ceramics industry.

It is suitable for marble, granite, jade, bluestone, Blackstone and other stone materials, as well as ceramics, glass, plexiglass, PVC board, aluminium-plastic board, bamboo and wood materials.

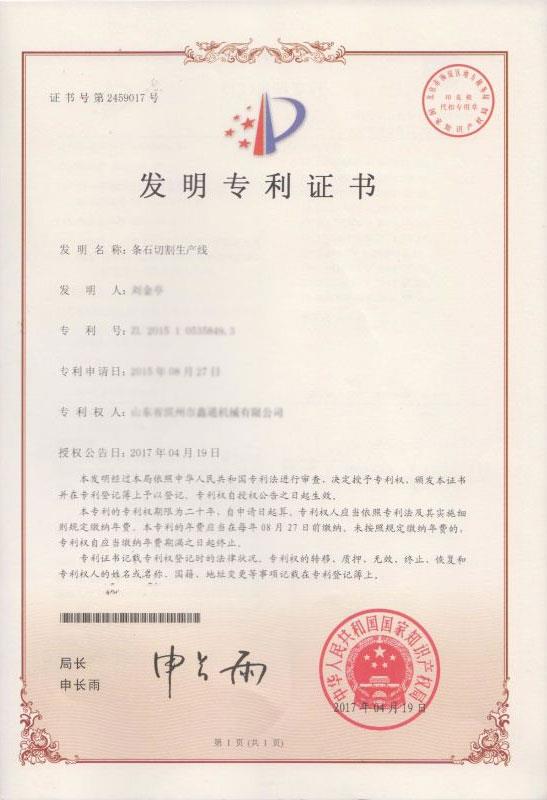

5 . Product Qualification of the Single Head Stone Engraving Machine

6 .Deliver,Shipping And Serving of the Single Head Stone Engraving Machine

7. FAQ

Q:What if the machine breaks down?

答:只要你是在保修期内,you can enjoy the free maintenance service of the original factory.

Q:How long is the warranty?

A:All machine mainframes are guaranteed for one year and spindle for six months. Accessories consumables excepted. If the machine fails, we will replace the new parts for you. You only need to return the old parts to us after the normal operation of the machine.

Q:How do I pay?

A:It is recommended that you use T/T or T/C for payment.

8 .Latest News

Sambin Machinery Co.,Ltd introduces that Stone Engraving Machine is an energy-efficient stone equipment, which is favored by customers. The use of machinery is a very important issue, which has a great impact on production. So what should we pay attention to in the use of stone carving machine? We will analyze and explain for you.

1.Theoretical basis: The training work must start from the theoretical training work, and the operators must pass the theoretical examination before they can carry out the practical operation training. If the theoretical training fails, the operational training must not be carried out.

2. The use of cutting tools in stone carving machine: after theoretical training, the training of cutting tools must be carried out. Operators should be familiar with the application of common cutting tools, the speed of engraving motor, the speed of moving, matters needing attention and so on.

3. Application scope of stone: Operators must be familiar with the application scope of various materials, different materials, different thicknesses, different sizes of finished products and so on. Familiar with different carving methods of different materials.

4. The operation of various software of stone carving machine: after the above training, software training can be carried out. Software training is mainly concentrated in the field of user application; software requirements are: software layout, various operations, path generation, can quickly find the path of errors, and so on.