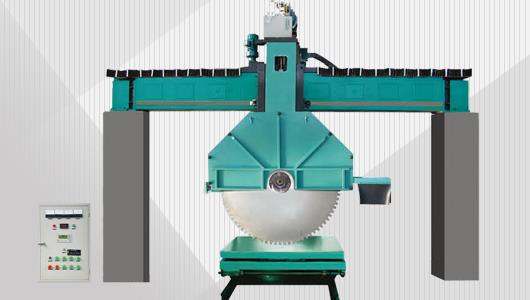

The hydraulic bridge disc diamond circular stone sawing machine adopts the hydraulic rotation as its rotation mode, so this machine is different from the bridge circular sawing machine. This type of rotation greatly increases the speed of the blade moves up and down. It cuts the cutting time from 3 seconds to 0.2 seconds, after cutting finished,itsaves about 1 minute.

Each 15 to 30 sheets are processed to produce one more sheet, while hydraulic rotation reduces equipment failure and equipment use costs.

The oil pump of the system adopts the gear pump used in the construction machinery with long service life. The gear pump has good durability and high efficiency.

The hydraulic rotary electromagnetic reversing valve ensures smooth movement in polluted environment.Another difference is that the hydraulic diamond saw is operated by numerical control, which makes it more intelligent.

Several features

1. suitable for cutting all kinds of hardness stone even more than 5mm thickness of marble and granite.

2. Cutting with high flatness,low broken rate ,high yield ,low cost and efficient advantages.

3. 20-40T/1800×1800mm bearing,roller type rotary tub.Rotary table can be 30mm steel plate.

4. Host of walking the oil immersed type dovetail structure,frequency conversion stepless speed regulation,sliding parts installed advanced wear-resistant materials,running stable and durable.

5. User can choose different control system to realize the automatic operation of the equipment.

Main technique parameter

Data category |

QJS120-160 |

QJS180-200 |

QJS220 |

Saw blade diameter |

Φ900mm-Φ1600mm |

Φ1800mm-Φ2000mm |

Φ2200mm |

Trasverse effective stroke of saw blade |

2600mm |

3100mm |

3600mm |

Effective stroke of saw blade lift |

850mm |

1100mm |

1100mm |

Total installed power |

24.85千瓦 |

32.85kw |

40.55kw |

Mounting dimensions(L*W*H) |

6000×200×4100mm |

7300×5150×6800mm |

7800×5150×6800mm |

weight |

4800kg |

7000kg |

7500kg |

QJS220D |

QJS260 |

QJS260D |

QJS280-300 |

Φ1650mm×3 Φ1800mm×2 |

Φ2400mm- Φ2600mm |

Φ1800mm×3 Φ2000mm×2 |

Φ2800mm- Φ3000mm |

3600mm |

4100mm |

4100mm |

4600-9100mm |

1100mm |

1300mm |

1300mm |

1400-1600mm |

40.55mm |

40.55mm |

48.55mm |

48.55mm |

7800×5150×6800mm |

8200×5150×7000mm |

8200×5150×7000mm |

8200×5150×7000mm |

7800kg |

8000kg |

8300kg |

Over 8500kg |

Several Pictures